In today's fast-paced industrial environment, the need for reliable and efficient technology is paramount. As industries continue to evolve, industrial monitors have emerged as essential tools for enhancing productivity and operational efficiency. According to Dr. Emily Carter, a leading expert in industrial automation, "The right industrial monitor can transform the way organizations interact with their systems, allowing for real-time data analysis and improved decision-making." These specialized displays are designed to withstand harsh conditions, ensuring that operators have access to crucial information at all times.

As the demand for streamlined operations increases, the selection of an industrial monitor becomes a pivotal decision for companies looking to optimize their workflows. From manufacturing plants to shipping warehouses, the integration of high-quality monitors can lead to significant advancements in both productivity and reliability. With features such as enhanced visibility in challenging lighting conditions and durability against dust and moisture, modern industrial monitors cater to the specific needs of varied environments.

In this comprehensive guide, we will explore the 10 best industrial monitors available in the market today. By examining their key features, benefits, and performance, we aim to help businesses make informed choices that enhance their operations and drive success in an increasingly competitive landscape.

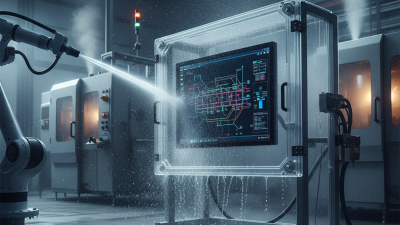

When selecting industrial monitors, certain key features can significantly enhance productivity and reliability in demanding work environments. One essential aspect is the display quality; a high-resolution screen with anti-glare capabilities ensures clear visibility even in bright lighting conditions. Furthermore, monitors should be rugged and durable, capable of withstanding harsh conditions such as extreme temperatures, dust, and moisture. Look for models with an IP rating that indicates their resistance to environmental factors.

Another important feature is connectivity. Industrial monitors should offer multiple connectivity options such as HDMI, DisplayPort, and USB ports to ensure compatibility with various devices and systems in an industrial setting. Additionally, consider touch functionality; touchscreens can streamline operations, allowing for easier interaction with software applications used in factories and warehouses.

Tips: Ensure you consider the monitor's mounting options, as flexibility in installation can be crucial in optimizing your workspace. Furthermore, check for additional functionalities, such as integrated safety features or power-saving modes, which can contribute to both efficiency and cost-effectiveness in the long run. Being aware of these key features before purchasing your industrial monitor will lead to better decision-making and improved overall performance in your operational processes.

When it comes to industrial monitors, the selection of top brands is crucial for businesses aiming to enhance productivity and reliability in their operations. Leading manufacturers prioritize durability, ensuring their monitors can withstand harsh environments and extended use typical in industrial settings. These brands also focus on advanced technologies that offer high resolution, wide viewing angles, and touch capabilities, which are essential for seamless interaction and visibility in various lighting conditions.

Moreover, reputable brands in the industrial monitor market consistently emphasize exceptional customer support and warranty services. This build of trust allows companies to feel assured that they are investing in high-quality products. Additionally, these brands often conduct rigorous testing to meet industry standards, providing customers with peace of mind regarding performance and longevity. By choosing monitors from these trusted names, businesses can significantly boost their operational efficiency and reliability, thus reaping the rewards of an optimized workplace.

When evaluating industrial monitors, understanding the different display technologies is crucial for ensuring enhanced productivity and reliability in various environments. The most common types of display technologies include LCD, LED, and OLED. LCDs, or Liquid Crystal Displays, are widely used due to their cost-effectiveness and ability to deliver high-resolution images. They operate on a backlighting system, making them suitable for environments with stable lighting conditions. However, their performance can be hampered in direct sunlight, which is a key consideration for outdoor industrial settings.

In contrast, LED technology offers improved brightness and energy efficiency compared to traditional LCDs. LED monitors utilize light-emitting diodes for backlighting, resulting in deeper blacks and better color accuracy. This capability makes them ideal for applications that demand precise visual details and consistent performance in varying lighting conditions. Meanwhile, OLED technology presents its own advantages, featuring self-emissive pixels that provide exceptional contrast ratios and vibrant colors. This technology allows for thinner displays and can be particularly beneficial in applications where space is limited or where high-level visual fidelity is required. By carefully comparing these technologies, industrial operators can select monitors that not only meet their specific operational needs but also contribute to overall productivity and system reliability.

In today’s fast-paced industrial environments, the integration of high-quality monitors has become vital for enhancing productivity and reliability. Industrial monitors are specifically designed to withstand harsh conditions, including extreme temperatures, dust, and moisture, which are prevalent in manufacturing and logistics. According to a recent report by MarketsandMarkets, the global industrial display market is predicted to grow from $6.9 billion in 2021 to $11.1 billion by 2026, reflecting a growing recognition of the importance of these specialized devices in enhancing operational efficiency.

The effectiveness of industrial monitors in boosting productivity can be attributed to several key features. Their ability to deliver high-resolution images ensures that operators can easily interpret complex data, which is crucial in making real-time decisions. Additionally, many industrial monitors support multi-touch technology, enabling operators to interact with systems through intuitive gestures, thus reducing the time taken for training and familiarization. A study published by the International Journal of Production Research highlighted that companies that utilized ruggedized displays experienced a 25% reduction in operational downtime, directly correlating to improved productivity figures and enhanced reliability in work processes.

Furthermore, the adaptability of industrial monitors to various automation systems facilitates seamless integration, allowing for smoother workflows and communication between different sectors within a facility. Enhanced durability and performance in challenging environments help minimize disruptions, creating a more stable production line. As industries continue to evolve, the reliance on advanced industrial monitors illustrates their pivotal role in driving productivity and maintaining high standards of operational reliability.

When it comes to industrial monitors, maintaining their longevity is crucial for maximizing productivity and ensuring reliability in tough operating environments. According to a report by Research and Markets, the global industrial monitor market is expected to reach $6.9 billion by 2025, illustrating the increasing reliance on these devices. To keep them functioning optimally, regular maintenance should be a primary focus for facilities management teams. This includes performing routine checks on connections, cleaning the screens with appropriate materials, and ensuring that the ambient temperature and humidity levels are within the specified range to prevent overheating and moisture damage.

Another essential maintenance tip is to monitor the operating hours of the industrial monitors. A study by Grand View Research indicates that devices that are subjected to excessive usage without downtime can experience shorter lifespans. Implementing a usage schedule that allows for breaks will help avoid constant wear and tear. Additionally, utilizing surge protectors can safeguard against electrical fluctuations that may compromise the monitor's functionality. By following these best practices, organizations can enhance the performance of their industrial monitors and ultimately improve overall operational efficiency.